Conveying Industries Case Study

Palletizing Time-Sensitive Food Product In An Extreme Climate

RESULTS

• Robot can palletize up to 22 bags per minute, 18-20 bags per minute on average

• Number of operators needed for this process decreased by more than 50%

• Manual bagging system replaced with form-fill-seal bagging system

• Air conditioners mounted to robot controllers to prevent machine overheating

• Custom HMI allows for simple operation and troubleshooting

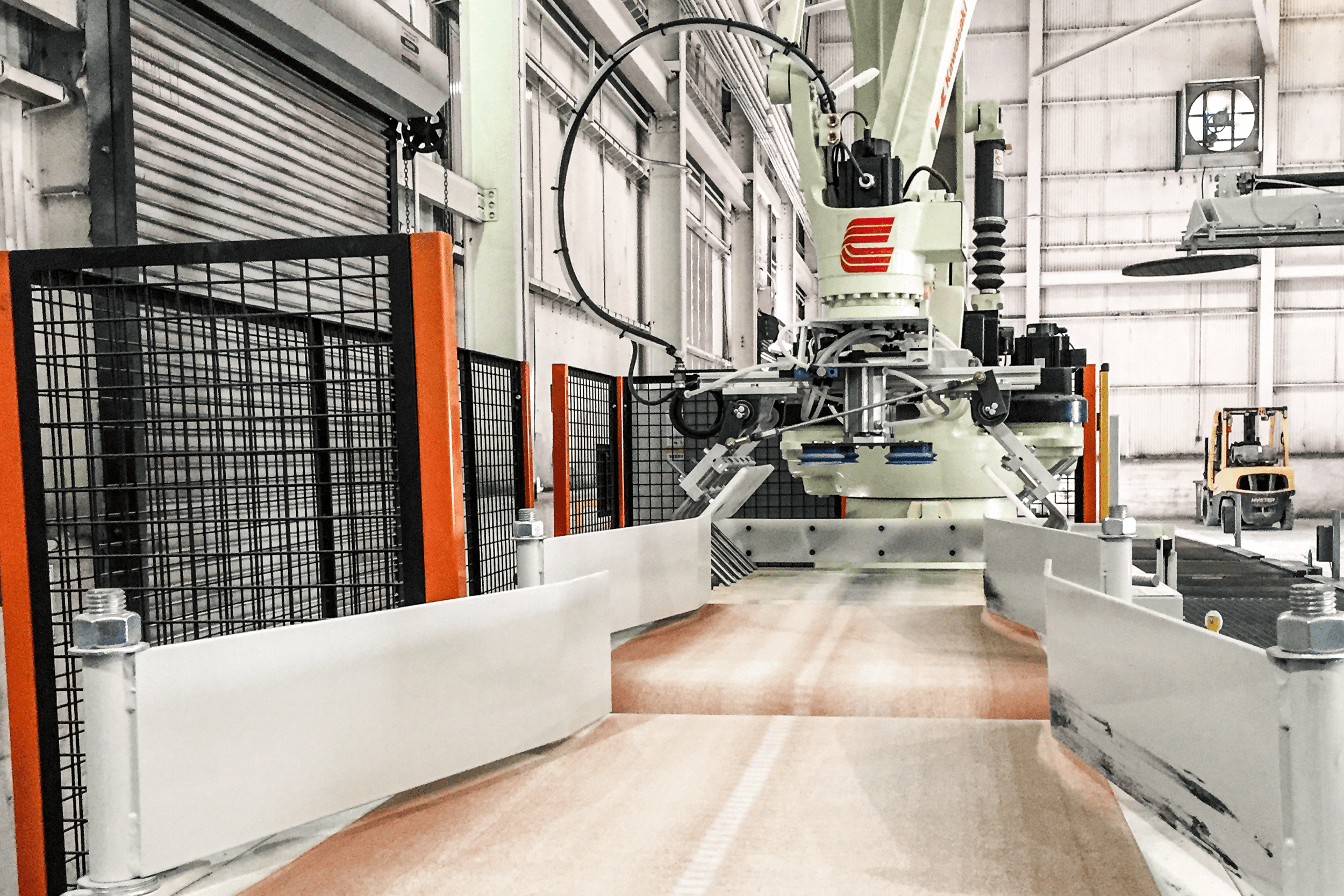

As machinery ages, should their dollars go toward fixing their line or replacing it altogether? Downtime caused by frequent breakdowns made the decision easy for this end user, who worked with Denver-based Kawasaki robot integrator Conveying Industries to revamp their entire line and upgrade their existing valve baggers, robotic palletizer and stretch wrapper with up-to-date equipment that was faster and more reliable than what they currently had.

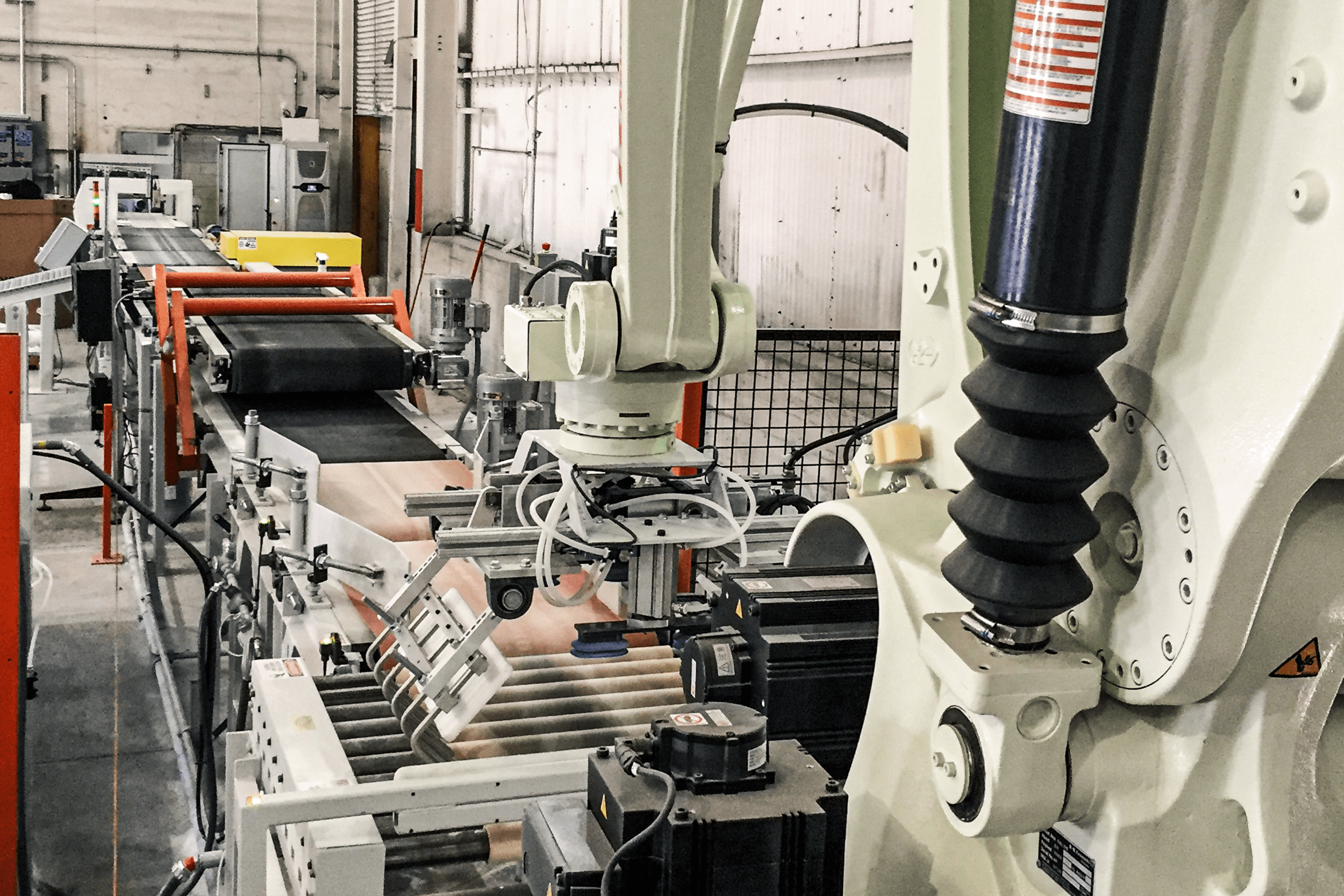

Another concern was the highly time-sensitive nature of the food product in this process. Once it’s made, the manufacturer has limited time to bag the product and start distribution before it’s deemed unusable. Any downtime would result in immediate, critical delays in production and bagging, which would result in a loss of sales.

The customer’s facility is located in southern California’s desert climate, where temperatures can reach up to 120° in the summer months. The region’s extreme conditions presented challenges for the integrator, who needed to ensure all equipment would be able to operate at such high temperatures.

With their previous robot, the end user could not achieve their production goals due to breakdown-induced lapses in production. Now, the Kawasaki CP180L is able to consistently palletize 20 bags per minute for hours a day with fewer operators. At full speed, the rate increases by 4 bags per minute from the previous robot’s capabilities. In addition, the new system only requires two operators as opposed to five – a benefit reflected in the customer’s bottom line.

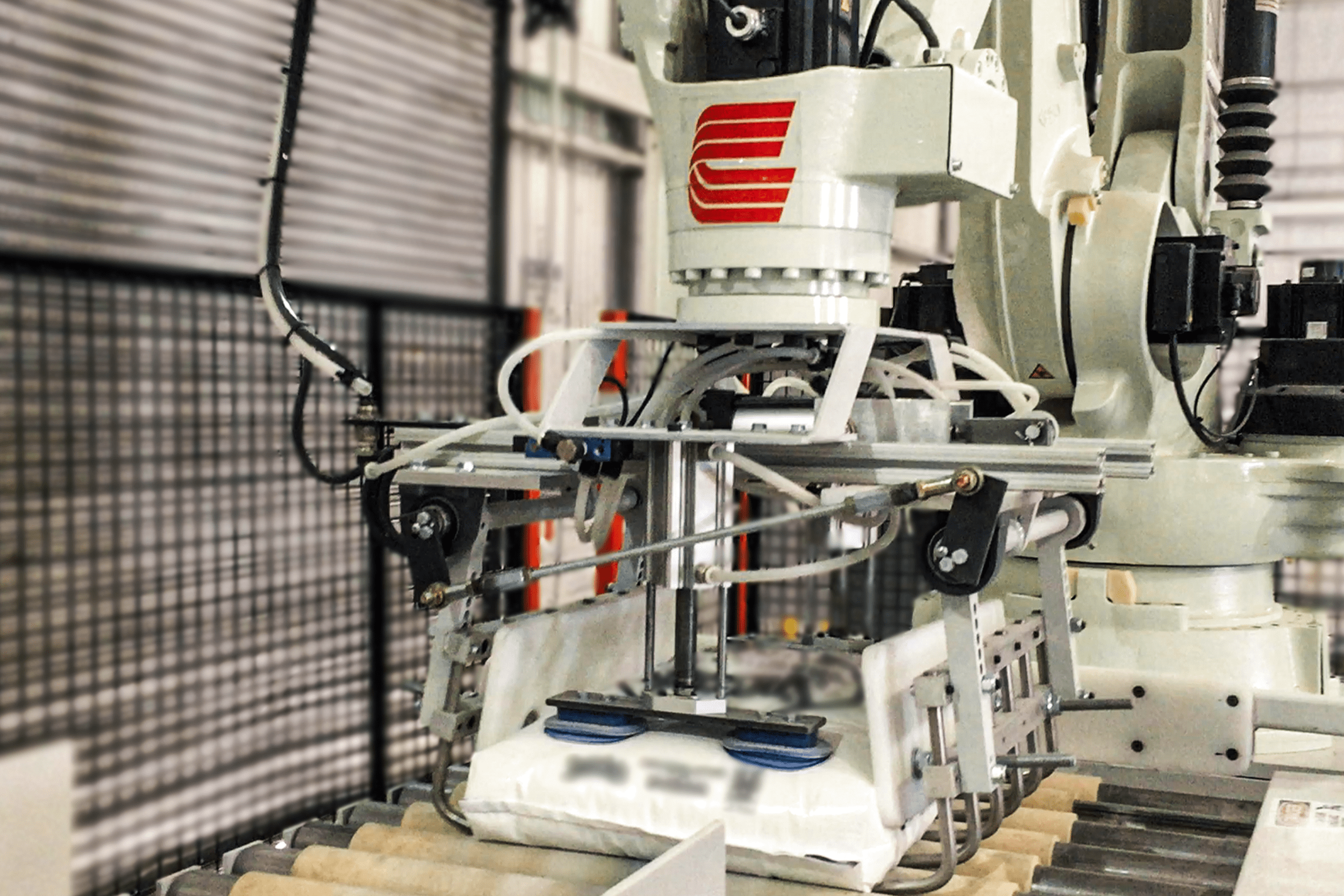

The combination of the Kawasaki CP180L robots’ simple design, high reliability, ruggedness and high palletizing speed with Conveying Industries’ custom-designed HMI interface and end-of-arm tooling resulted in a solution that suited the customer’s needs.